Gear Pump | Parts | Types | Applications |

What is gear Pump ?

Gear Pump

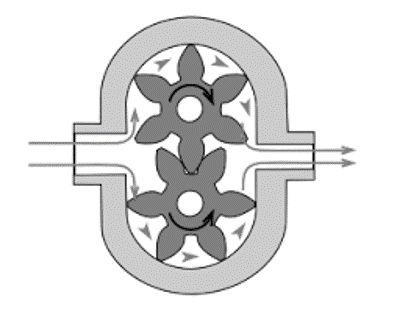

A gear pumps is a type of positive Displacement pump which uses the meshing of gears to pump fluid by displacement.

Gear Pump Working Principle

The gear pump working principle is explain briefly below:

When there is a revolution of toothed wheels inside of the casing section, air will get wedged in between and throughout the teeth which creates space. This shows a result of a positive up direction lift of the liquid on the way to the suction pump. The pump continues to pull in the air until it initiates to receive liquid through the inner section.

The liquid will be pulled into it at the level of atmospheric pressure; prior to being trapped in-between the space of two wheels. Gradually the viscous liquid will be pulled in the direction of output and then pulled towards the out. The pump functions effectively also in the inactive state but operates more actively when it got primed in before.

Added protection in the scenario of valve relieving is fitted in the gear type revolving pump so as to expel any kind of destruction either for the pipeline or pump. The relieving valve will decrease the additional pressure during emergency thus safeguarding the entire equipment.

Types of gear pump

there are mainly two types of gear ?

1.External Gear

2.Internal Gear

Parts of gear pump

1.Drive gear :-The Drive gear is connected to the prime mover . The power from the prime mover is used to rotate it. The prime mover is motor.

2.Driven gear :- The driven gear is meshed with drive gear. As drive gear rotates ,driven gear is rotated in opposite directions

3.Casing :- The driver and driven gears are both packed inside the gear pump’s casing.

4.Suction Side: The section of the gear pump from where fluid enters the gear pump. The Inlet Section is where low-pressure liquid enters the pump.

5.Discharge Side :- The discharge side of the gear pump is where pressurized fluid is delivered to the required area. The pump’s Outlet Section discharges high-pressure liquid.

6.Prime Mover: The prime mover in a gear pump is used to provide power to the shaft on which the driver gear is mounted. It could be an electric motor, an internal combustion engine, or manual labor.

Applications of Internal gear pumps

- Used in surfactants and soaps manufacturing

- Pigments, inks, and resins

- Used in food products like animal feed, cocoa butter, corn soups and in many

- Resins and Polymers

- Alcohols and solvents

- Asphalt, Bitumen, and Tar

- Polyurethane foam (Isocyanate and polyol)

- Glycol

What are the advantages and disadvantages of gear pumps?

Factors influencing gear pumps efficiency

Gear pumps are generally very efficient, especially in high-pressure applications.

The following factors influence pump efficiency:

1.Clearances:-Geometric clearances at the gear ends and outer diameters allow for leakage and back flow. Greater clearances, on the other hand, can sometimes help to reduce hydrodynamic friction and improve efficiency.

2.Backlash:-Due to high backlash between gears, fluid leakage is also possible. This, however, aids in preventing energy loss caused by fluid trapped between gear teeth (known as pressure trapping).